Linear or Non Linear Management Style? Tank Storage Awards 2020

What research

shows is that our industry is often managed by linear thinking and actions only

which makes management styles reactive rather than proactive or preventive.

Linear causality means cause and effect thinking, but our industry is too

complex to manage by an outdated cause and effect approach only. Linear

management depends on written procedures, guidelines, rules or compliance

methods to control risk and manage organisations. Younger, highly educated types of managers are

recruited, but often lack the needed on the job experience, making

communication between the workers and him or her difficult. This often

leads to decisions made on incomplete information. (THE MAIN CAUSE OF INCIDENTS

and ACCIDENTS)

Non linear

management to control complex systems such as our industry uses information as

its energy to steer the organisation (system), rather than control or regulate

it. Linear management is risky; I’ll give you some examples: Some technical

equipment is not working properly. According to the procedure and planning, the

next maintenance date is…. Let’s say in a few weeks. Management is prone

to wait for that date because the equipment is not considered critical. Another

example: operators report on a risky situation; at one of the truck loading

bays there is no fall protection available, but trucks load anyway. The manager

knows about this, but his clients are sending trucks that need to load there

and he is unable to suspend loading due to commercial interests. A third

example taken from my own experience; a mistake is made by an operator, so

management sends him to be trained. But the cause was not the mistake of the

operator. The cause is: he had been sent into the field without proper

preparation, so the mistake was not direct causal (by him) but by the failure

or management that did not do what it was supposed to do and that is to be

careful. These 3 examples have one thing in common: information was there but

was not used whilst complexity was misunderstood and therefore overlooked.

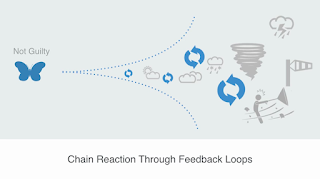

What happens

here is crucial to understand: information that is there should be used to

correct in real time (immediately). Real time corrections are often postponed or not

executed at all. From a scientific view point this is what is happening: the

terminal or refinery is spinning out of control. Linear management is simply

not enough. Remember the BP Oil Spill in Louisiana? Same causality; information

about possible flaws and broken equipment was ignored. What if a manager does

not understand what the operations are doing? Again it is the lack of

information…

So we have

created a scientifically sound training program for managers and supervisors to

learn how to manage their operations using non linear thinking and understand

the uncertainty principle. We teach them information theory, systems thinking

and cybernetics and explain their scientific bases during the course. They will

learn to look at relationships, interdependence of all the workers and

stakeholders, their information and interconnectedness. The program also

addresses sustainability issues, psychological biases and focuses on how to

improve communication, cooperation and conversation. It certainly enhances

sustainable and responsible, safer management, because all relevant

information is used all the time.

TTT has been

training people worldwide for the last 10 years. Our team worked as an operator, sailor,loading master, captain or manager many years and are always learning. The risk is that

managers believe that they already know, so they stopped learning. This

behaviour is very risky indeed. Epictetus told us 2000 years ago that 'a man

can’t learn what he thinks he already knows.'

This text was written to enter the 2020 Tank Storage Awards in the category Tank Terminal Optimisation.

This text was written to enter the 2020 Tank Storage Awards in the category Tank Terminal Optimisation.

Reacties

Een reactie posten